I started this project last year, the day after Trans Day Of Remembrance, and the day of the Club Q terror attack. My heart was heavy, and I needed a way to redirect a whole bunch of feelings about a thing I couldn't do anything about.

The warp and weft both came from several balls of a 5 ply acrylic knitting yarn. They had been given to me in one of those many small "I don't know what else to do with this" moments that happen when people know that 1) you're a knitter and 2) you'll happily collect donations and pass them on to various local organisations if you can't use them yourself.

|

| If you wrap the warp chain once around the cloth beam, it keeps tension on the warp while you're beaming it. Much easier to do the job solo that way. |

I'd looked at them and immediately went "that's a trans pride bundle of colours if ever I saw them," then put them in the stash and let them percolate. (I don't knit with 5 ply much, I already had more than enough projects that needed finishing, and I had no idea what pattern would do justice to the vague idea I had. Sometimes things need to compost a while before you can grow anything from them.)

|

| The warp, beamed and heddles threaded, ready to sley the reed. |

I originally wanted to do a heart twill. After a bit of thought, mostly centred around my lack of experience, I went with a diamond twill instead. This was the first project on my new-to-me floor loom, and the diamond twill was more straightforward.

Plus, counterbalance looms don't deal well with unbalanced shafts - you can certainly weave them, but they take a bit of experience, and it's best to have the majority of the threads on the front shafts rather than the back. The heart twill pattern I had put more threads on shafts 2 and 4 than on shafts 1 and 3, and I didn't have the headspace or the experience to flip the draft.

It took me eight days to wind the warp, beam it, thread the heddles, sley the reed, and tie on. (I wasn't tracking project hours back then, so I don't know how long those things actually took, all up. They certainly weren't full days.) I'd started on the twenty-first, and was threading the heddles by Sunday 27th. On the 30th, I started weaving.

It took me a little while to find a good beat - I started out far too soft, so I had to cut off the first few inches when I'd finished.

|

| Besides me not liking the look of the elongated diamonds, this beat would have resulted in a sleazy fabric. |

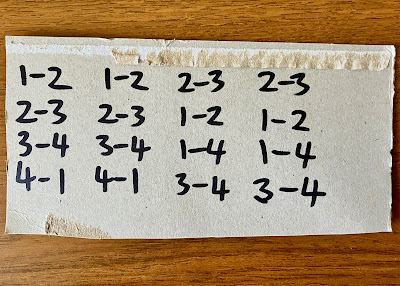

Once I got the beat figured out, it was (fairly) plain sailing. This diamond twill changes the treadling pattern every eight picks, so I had to pay attention at all times or I'd end up having to unweave sections. I ended up writing down the treadling plan on a piece of cardboard, and blu-tacked it to the castle. As I wove, I moved another blob of blu-tack along every "section" to keep my place.

Even with that help, I found I could only weave for 40 minutes at most before I got too scrambled to keep going. This was

not a project where I could put on a podcast in the background. (Good for ergonomics, not so great for getting things done in a timely fashion.)

According to my project notes, I only actually wove for eight days between getting the loom warped and cutting the finished fabric off. Given the thickness of the threads, that seems about right - I'd roughly guess at six or seven hours of weaving time over a ~2.3m warp.

|

| Fresh off the loom. |

After that it was a matter of wet finishing (I washed it on the wool setting, with a bunch of socks that needed cleaning, in the washing machine), trimming the loom waste and the weft ends, and doing double folded hems at each end (I am Not A Fan of fringe).

Draw-in was only about 2cm (0.75"), and take-up equally small at ~4cm (1.6"). There was practically no shrinkage when I wet finished it, too - I'm told that's common with acrylic. All up, the finished wrap is 161 cm (63.5") long and 67 cm (26.5") wide.

Is it perfect? Hell no; there's at least two threading errors and the beat changes from start to finish. But it's soft, and warm, and it's full of the hope and productive anger that I managed to find after the beat of the loom helped me climb out of the pit of helpless despair.